SDTR1103-HF2-0020K

X/Y axis SMD Transponder Coil for NFC...

5,00 €

127 In Stock

Menus

| L (µH) | Q Min | Height (mm) | Length (mm) | Width (mm) | Freq. (kHz) | DCR (Ω) Max | Tolerance | SRF (MHz) Min |

|---|---|---|---|---|---|---|---|---|

| 20 | 20 | 2.5 | 11.8 | 3.6 | 13560 | 1.32 | ±10% | 25 |

| 1 | 20 | 2.5 | 11.8 | 3.6 | 13560 | 0.286 | ±10% | 25 |

| 2 | 20 | 2.5 | 11.8 | 3.6 | 13560 | 0.4345 | ±10% | 25 |

| 3 | 20 | 2.5 | 11.8 | 3.6 | 13560 | 0.506 | ±10% | 25 |

| 6 | 20 | 2.5 | 11.8 | 3.6 | 13560 | 0.704 | ±10% | 25 |

|

Samples: MOQ 5 units.

| L (uH) | Tolerance | Q Min | Frequency (kHz) | DCR (Ω) Max | SRF (MHz) Min | Length (mm) | Width (mm) | Height (mm) | |

|---|---|---|---|---|---|---|---|---|---|

| SDTR1103-HF2-0001K | 1 | ±10% | 20 | 13560 | 0.286 | 25 | 11.8 | 3.6 | 2.5 |

| SDTR1103-HF2-0002K | 2 | ±10% | 20 | 13560 | 0.4345 | 25 | 11.8 | 3.6 | 2.5 |

| SDTR1103-HF2-0003K | 3 | ±10% | 20 | 13560 | 0.506 | 25 | 11.8 | 3.6 | 2.5 |

| SDTR1103-HF2-0006K | 6 | ±10% | 20 | 13560 | 0.704 | 25 | 11.8 | 3.6 | 2.5 |

| SDTR1103-HF2-0020K | 20 | ±10% | 20 | 13560 | 1.32 | 25 | 11.8 | 3.6 | 2.5 |

.jpg)

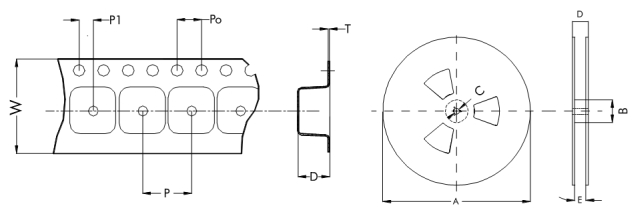

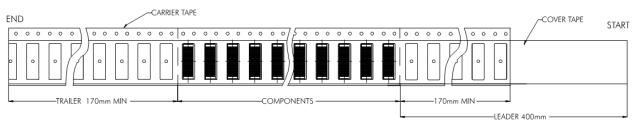

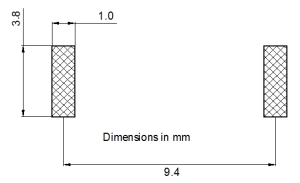

| Reel dimensions | Tape dimensions | PARTS/REEL | |||||||||

| A | B | C | D | E | W | P | P0 | P1 | D | T | |

| 330 | 50 | 13 | 30.4 | 24.4 | 24 | 8 | 4 | 2 | 2.7 | 0.3 | 3000 |

All dimensions in mm.

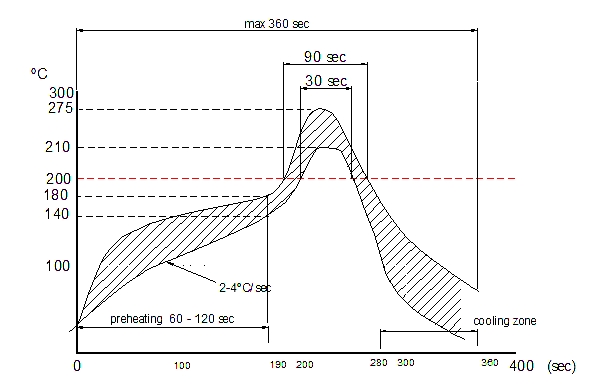

Reflow soldering, vapour-phase soldering. A maximum soldering temperature of 260ºC during 10 s should not be exceed for (see recommended soldering profile with maximum and minimum temperature-time).

The reflow condition recommended is according to the machine used by our company. Big differences will arise as a result of the type of machine, reflow conditions, method, etc used.