TP0702CAP - X/Y axis SMD Hard Ferrite Transponder Coil CAP Protected 125kHz / 2.38-9mH / 8.7x2.7x3mm

- picture_as_pdfDownload Data Sheet

- Characteristics

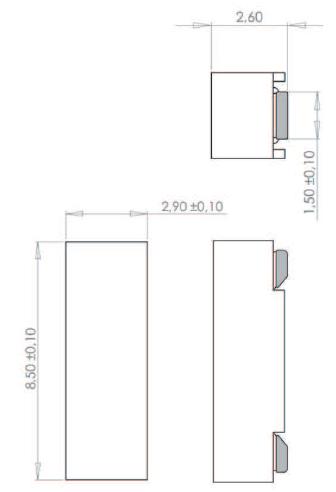

- Dimensions

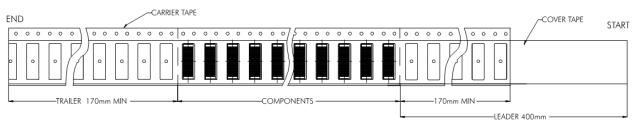

- Packaging

- Cad Models

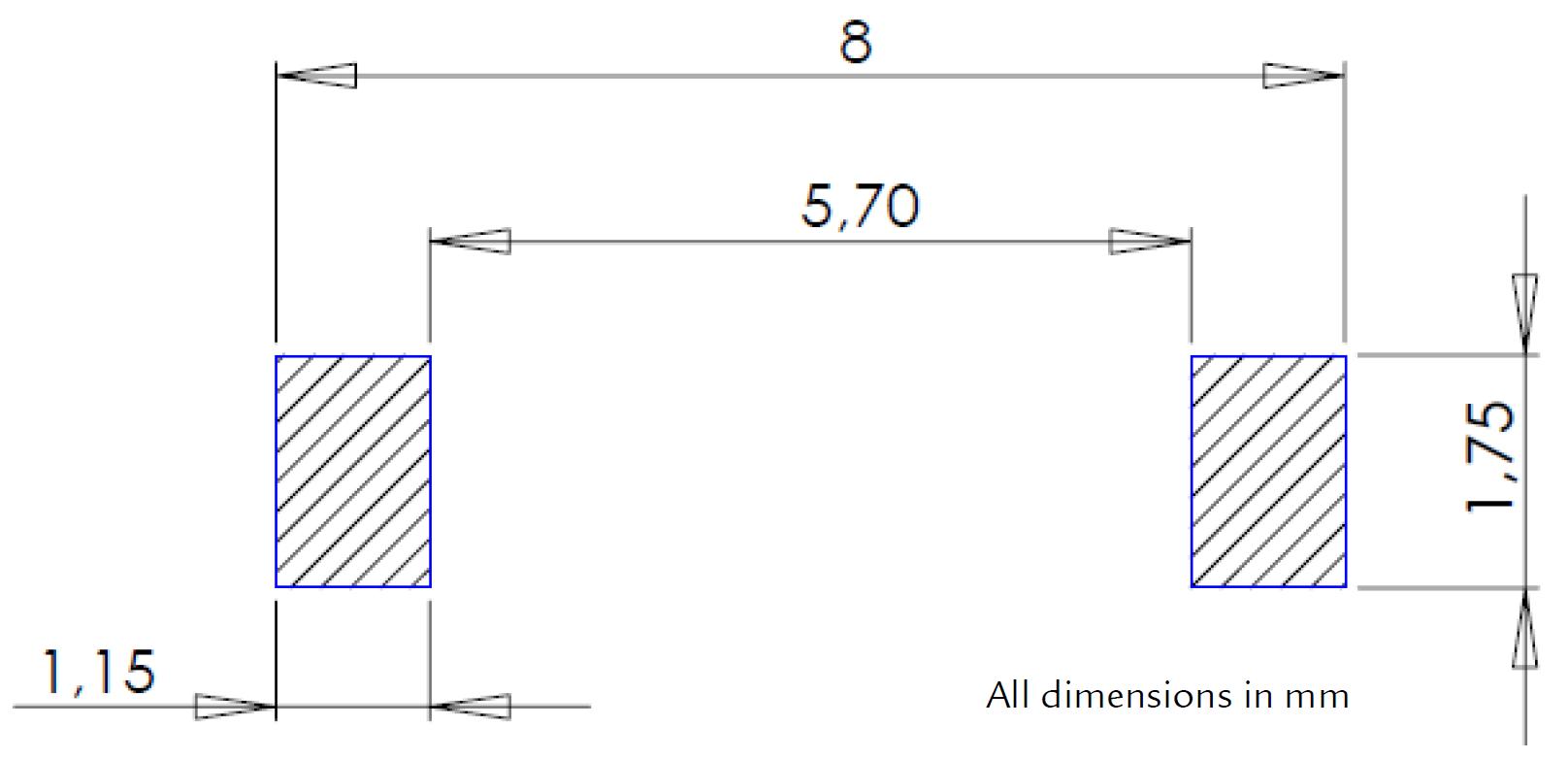

- Pad Layout

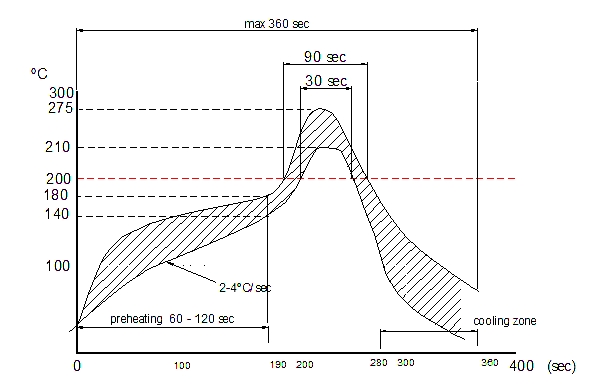

- Soldering

- Measurement Conditions

| Freq. (kHz) | L (mH) | Q Min | Sensitivity (mVpp/App/m) Min | Height (mm) | Length (mm) | Width (mm) | SRF (kHz) Min | Tolerance | Cres (pF) | DCR (Ω) Max |

|---|---|---|---|---|---|---|---|---|---|---|

| 125 | 2.38 | 20 | 25 | 2.7 | 8.6 | 3 | 750 | ±5% | 680 | 51 |

| 125 | 4.91 | 22 | 50 | 2.7 | 8.6 | 3 | 500 | ±5% | 330 | 71 |

| 125 | 7.20 | 18 | 47 | 2.7 | 8.6 | 3 | 450 | ±5% | 220 | 147 |

| 125 | 9.00 | 18 | 47 | 2.7 | 8.6 | 3 | 400 | ±5% | 180 | 165 |

X/Y axis SMD Hard Ferrite Transponder Coil CAP Protected

This TP0702 with CAP is a very strong solution in very small dimensions. The

component has very good electrical properties and it is a very good solution for RTPMS,

Keyless Go and Keyless Entry Systems. On the other hand, the plastic box, where it is

inserted the piece, offers a special protection to the wound and facilitates the pick and

place

|

Applications:

Due to its small dimensions, it’s a suitable design for other applications working at lower frequencies.

- Terminals: Ag-Ni-Sn100.

- Wire: H, 180ºC, Solderable.

- Max. Operating Temperature 150ºC.

The specification chart is a reference guide for the most common required values at working frequencies of 125 kHz. Any other inductance value at LF or tighter tolerances can be provided. Please contact our sales deparment for any inquiry.

This product has a datasheet available upon request.

| L (mH) | Tolerance | Q Min | Frequency (kHz) | Cres (pF) | SRF (kHz) Min | DCR (Ω) Max | Sensitivity (mVpp/App/m) Min | Length (mm) | Width (mm) | Height (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| TP0702CAP-0238J | 2.38 | ±5% | 20 | 125 | 680 | 750 | 51 | 25 | 8.6 | 3 | 2.7 |

| TP0702CAP-0491J | 4.91 | ±5% | 22 | 125 | 330 | 500 | 71 | 50 | 8.6 | 3 | 2.7 |

| TP0702CAP-0720J | 7.20 | ±5% | 18 | 125 | 220 | 450 | 147 | 47 | 8.6 | 3 | 2.7 |

| TP0702CAP-0900J | 9.00 | ±5% | 18 | 125 | 180 | 400 | 165 | 47 | 8.6 | 3 | 2.7 |

.jpg)

.jpg)

| Reel dimensions | Tape dimensions | PARTS/REEL | |||||||||

| A | B | C | D | E | W | P | P0 | P1 | D | T | |

| 330 | 50 | 13 | 30.4 | 24.4 | 16 | 8 | 4 | 2 | 2.9 | 0.3 | 2500 |

All dimensions in mm.

Recommended reflow profile.

Reflow soldering, vapour-phase soldering. A maximum soldering temperature of 260ºC during 10 s should not be exceed for (see recommended soldering profile with maximum and minimum temperature-time).

The reflow condition recommended is according to the machine used by our company. Big differences will arise as a result of the type of machine, reflow conditions, method, etc used.

- Rated Inductance LR: Measured at frequency fL, with impedance analyser WK3260 with 3MHz installed.

- Q Factor Qmin: Measured at frequency fL, with impedance analyser WK3260 with 3MHz installed.

- Self-resonance frequency fmin: Measured at frequency fL, with impedance analyser WK3260 with 3MHz installed.

- DC resistance Rmax: Measured at 20ºC ambient temperature, measuring current <IR.

- Sensitivity: Measured with Helmholtz coils 5 turns, 160mm ∅, + waveform generator Agilent 33120A + oscilloscope Agilent 54622A. Contact PREMO RFID for complete measurement specification.