3DC11LP - 3DCoil isotropic SMD for Transponder 125kHz / (2.38-7.20mH) / 13x11.6x3.15mm.

- picture_as_pdfDownload Data Sheet

- Characteristics

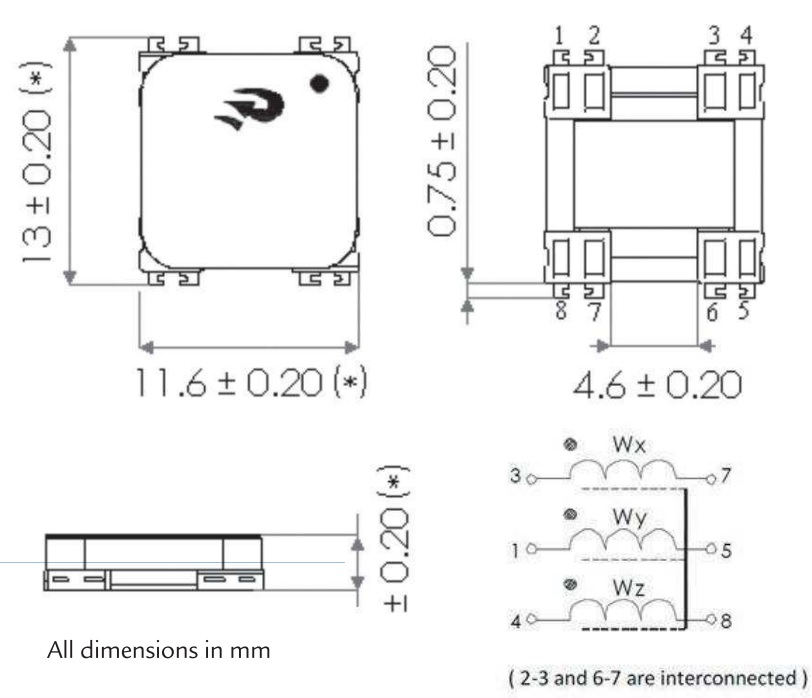

- Dimensions

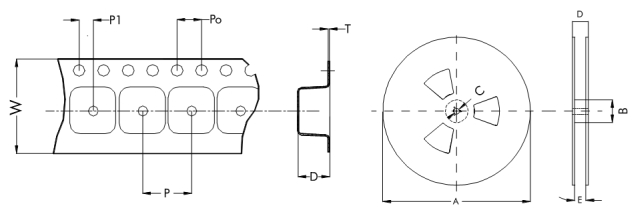

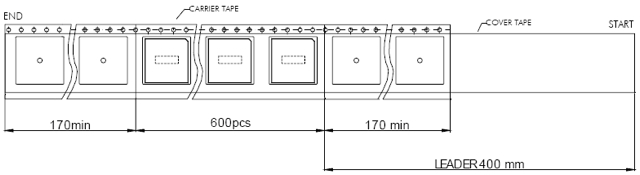

- Packaging

- Cad Models

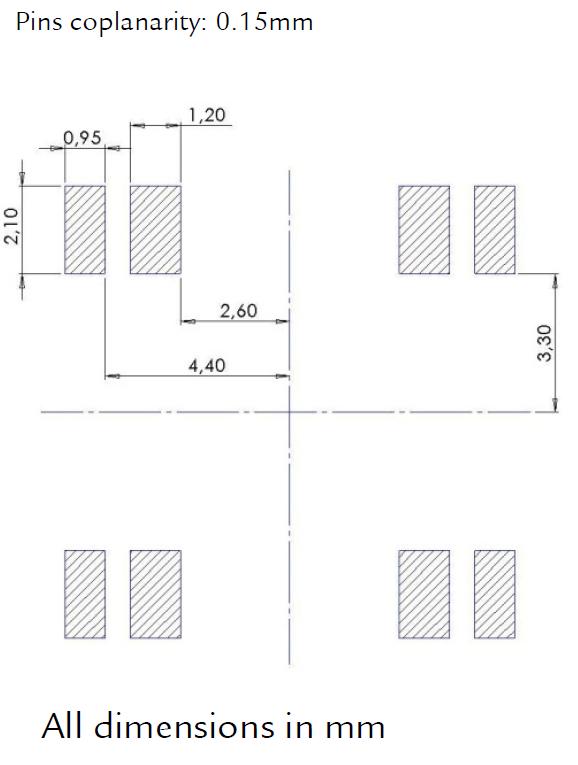

- Pad Layout

- Electrical Diagram

- Soldering

- Measurement Conditions

- Graphs

- Custom Product

- Others

Product

| Freq. (kHz) | Lx (mH) | Ly (mH) | Lz (mH) | Qx Min | Qy Min | Qz Min | Height (mm) | Length (mm) | Width (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 125 | 2.38 | 2.38 | 2.38 | 18 | 18 | 18 | 3.15 | 13.0 | 11.6 |

| 125 | 4.91 | 4.91 | 4.91 | 18 | 18 | 18 | 3.15 | 13.0 | 11.6 |

| 125 | 7.2 | 7.2 | 7.2 | 15 | 15 | 15 | 3.15 | 13.0 | 11.6 |

| 125 | 2.47 | 2.47 | 2.47 | 17 | 17 | 17 | 3.15 | 13.0 | 11.6 |

| 125 | 3.45 | 3.45 | 3.45 | 15 | 15 | 15 | 3.15 | 13.0 | 11.6 |

| 125 | 4.05 | 4.05 | 4.05 | 15 | 15 | 15 | 3.15 | 13.0 | 11.6 |

| 125 | 4.77 | 4.77 | 4.77 | 15 | 15 | 15 | 3.15 | 13.0 | 11.6 |

| 20 | 20 | 20 | 20 | 5 | 5 | 5 | 3.15 | 13.0 | 11.6 |

| 125 | 10 | 10 | 10 | 14 | 13 | 18 | 3.15 | 13 | 11.6 |

Showing 1 - 9 of 9 items

Downloads

Characteristics

3DCoil isotropic SMD for Transponder

Small 3D coil version designed to achieve a very good electrical performance in the smallest dimensions.

Keyless entry systems is a typical application for this coil, the isotropy is often sought in RF antenna. In transponder applications,this feature has been achieved by thecombination of 3 single coils oriented in the 3 space axis with the aim of covering the maximum space orientation. This small size 3D coil offers the possibility of assembly in single component 3 coils with full functionality, thus reducing cost, saving PCB space and increasing the circuit reliability.

- Smallest size 13x11.6x3.20 mm.

- Very good electrical performance.

- High stability in temperature (-40 ºC to +85 ºC).

- The inductivity in each axis can be customized to achieve customer requirements.

- Designs at lower frequencies like 20 kHz and 40 kHz show a very good electrical performance as well.

- High sensitivity values.

Applications:

- Automotive Passive keyless entry systems.

- Automotive RTPMS with wake up functions.

- Industrial logistics and control.

- Access control.

- Tracking devices.

The specification chart is a reference guide for the most common required values at working frequencies of 125 kHz. Any other inductance value at LF or tighter tolerances can be provided. Please contact our sales deparment for any inquiry.

This product has a datasheet available upon request.

| L x,y,z (mH) | Q x,y,z Min | Frequency (kHz) | Cres (pF) | SRF x,y (kHz) Min | SRF z (kHz) Min | DCR x,y (Ω) Max | DCR z (Ω) Max | Sensitivity x,y,z (mVpp/App/m) Min | Length (mm) | Width (mm) | Height (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3DC11LP-0238J | 2.38 | 18 | 125 | 680 | 450 | 900 | 60,5 | 82,5 | 40 | 13.0 | 11.6 | 3.15 |

| 3DC11LP-0247J | 2.47 | 17 | 125 | 656 | 450 | 900 | 68 | 82,5 | 50 | 13.0 | 11.6 | 3.15 |

| 3DC11LP-0345J | 3.45 | 15 | 125 | 470 | 350 | 800 | 100 | 121 | 55 | 13.0 | 11.6 | 3.15 |

| 3DC11LP-0405J | 4.05 | 15 | 125 | 400 | 300 | 600 | 100 | 138 | 60 | 13.0 | 11.6 | 3.15 |

| 3DC11LP-0477J | 4.77 | 15 | 125 | 340 | 320 | 600 | 100 | 150 | 70 | 13.0 | 11.6 | 3.15 |

| 3DC11LP-0491J | 4.91 | 18 | 125 | 330 | 300 | 600 | 100 | 160 | 70 | 13.0 | 11.6 | 3.15 |

| 3DC11LP-0720J | 7.20 | 15 | 125 | 225 | 250 | 500 | 165 | 209 | 85 | 13.0 | 11.6 | 3.15 |

| 3DC11LP-A-2000J | 20 | 5 | 20 | 3166 | 120 | 350 | 495 | 385 | 22 | 13.0 | 11.6 | 3.15 |

Dimensions

Packaging

| Reel dimensions | Tape dimensions | PARTS/REEL | |||||||||

| A | B | C | D | E | W | P | P0 | P1 | D | T | |

| 330 | 50 | 13 | 30.4 | 24.4 | 24 | 16 | 4 | 2 | 4.2 | 0.3 | 1000 |

All dimensions in mm.

CAD MODELS

PAD LAYOUT

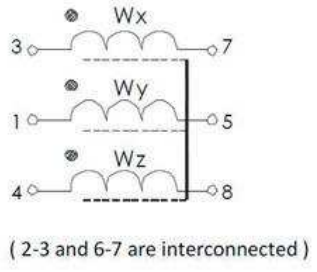

ELECTRICAL DIAGRAM

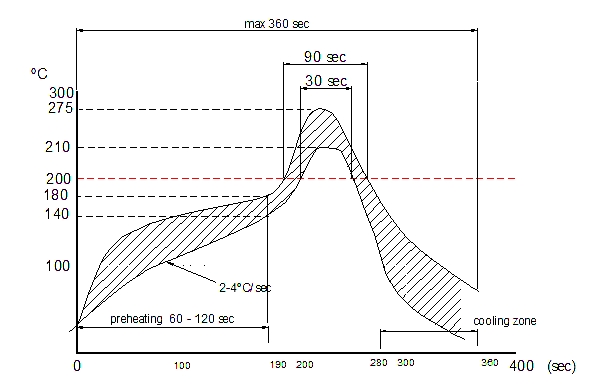

SOLDERING

Recommended reflow profile.

Reflow soldering, vapour-phase soldering. A maximum soldering temperature of 260ºC during 10 s should not be exceed for (see recommended soldering profile with maximum and minimum temperature-time).

The reflow condition recommended is according to the machine used by our company. Big differences will arise as a result of the type of machine, reflow conditions, method, etc used.

MEASUREMENT CONDITIONS

- Rated Inductance LR: Measured at frequency fL, with impedance analyser WK3260 with 3MHz installed.

- Q Factor Qmin: Measured at frequency fL, with impedance analyser WK3260 with 3MHz installed.

- Self-resonance frequency fmin: Measured at frequency fL, with impedance analyser WK3260 with 3MHz installed.

- DC resistance Rmax: Measured at 20ºC ambient temperature, measuring current <IR.

- Sensitivity: Measured with Helmholtz coils 5 turns, 160mm ∅, + waveform generator Agilent 33120A + oscilloscope Agilent 54622A. Contact PREMO RFID for complete measurement specification.

Graphs

Custom Product

Others