>HUB > Automotive EV > Practical Guidelines for the Litz Wire Selection and AC Copper Losses Estimation Applied to Resonant Power Magnetics used in Automotive Converters – Part 2

>HUB > Automotive EV > Practical Guidelines for the Litz Wire Selection and AC Copper Losses Estimation Applied to Resonant Power Magnetics used in Automotive Converters – Part 2Post - Automotive EV

Practical Guidelines for the Litz Wire Selection and AC Copper Losses Estimation Applied to Resonant Power Magnetics used in Automotive Converters – Part 2

Applied to Resonant Power Magnetics used in Automotive Converters - Part 2

Litz wire conductors are well known and massively used in magnetic components dedicated to power electronic applications to reduce copper losses versus frequency. However, their modelization could remain complex or not fully fixed for an accurate prediction of the final temperature rise in the windings of switching transformers or resonant inductors. The best wire selection and an accurate computing of its losses remain at first position for high power density converters optimization. This article is the second one in a two-part series. By Patrick Fouassier & Benoit Battail, PREMO FRANCE Inductive Components R&D

Litz Wire Models

State of the Art

Application of rules for Litz wire selection or further copper losses estimation remains an experimental approach. Litz wire suppliers can propose some formulas for strand diameter definition, number of strands per bundle, maximum estimated overall diameter [3]… but any accurate calculation method of winding loss at given operating frequency and ripple of current is always missing. For instance, application of 1D or 2D standard Dowell’s approach cannot be directly applied to the case of Litz wire copper subdivision.

Fortunately, Litz wire modeling has been questioning a lot of Universities, Research Centers, Companies’ advanced R&D Departments for years. Thanks to many investigations in this, a huge number of methods and scientific publications has been released [9,10,11]. However, most of the time formulas, applied hypothesis and computing methods can remain totally illegible for engineers from the Industry who must be able to quickly estimate the loss of their magnetic component design.

More applied research efforts have led to some easier analytical approaches including the development of freeware that you can easily find from the Internet [12].

However, the behavior of Litz wire and the resulting AC losses when used in winding construction shall still depend on the turns and layers arrangement with or without interleaving, generating integrated leakage inductance to fix serial inductance values in series with a resonant transformer…

Most of the case, data are not sufficient for any good prediction of the losses in frequency. Using Finite Element Analysis electromagnetic software seem the only solution to compute accurate copper losses depending on frequency operation and current waveform. However, what tool can be used today ? With which model for Litz wires ? Have they been fully evaluated by the Industry to consider them as fully reliable design tools?

Trying Strand Level 3D Modelization

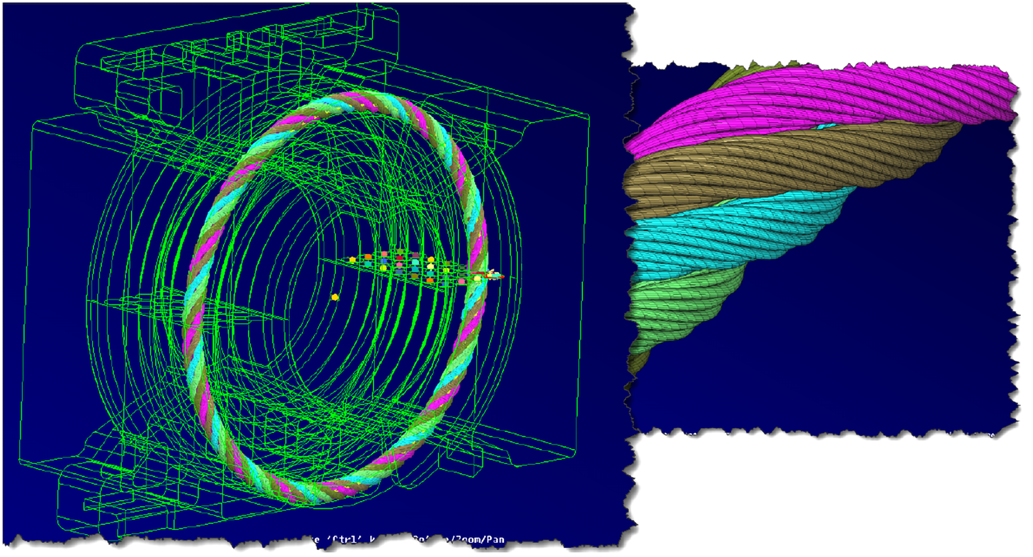

One first possible approach to introduceLitz wire model is to consider the wire at full definition with the most accurate twisting of the strands representation from the conductor datasheet (including number of bundles and pitch). Of course, special computing techniques are required to form turns and windings with this resolution. Some companies have been developing auto-meshing software to propose so.

One trial was performed with DEP MESHWORKS team and HEX Process Automation tool [13]. The case of a 250×0.1 Litz wire in 5 bundles of 50 strands was introduced as turns around a PQ59/35 core (figure 10). The output is a super heavy file (3Go) not easy to import and to make it run in further simulation tools. For instance, up to now, the output format is still not compatible with ANSYS MAXWELL electromagnetic FEA software. Besides, the calculation time becomes so long that such a method has a clear limit from this standpoint.

2D/3D FEA Software with Litz Model Integration

Hopefully, some FEA software for electromagnetic simulation include a Litz wire model programmed from analytical approaches usually based on complex permeability assigned to the conductor

[14,15,16]. This is one robust and quick method to compute frequency effects in conductor. The model is sensitive to skin effect depending on the strand thickness and number of strands introduced. When applied in a simulated geometry, proximity and fringing flux effects will be treated at once.

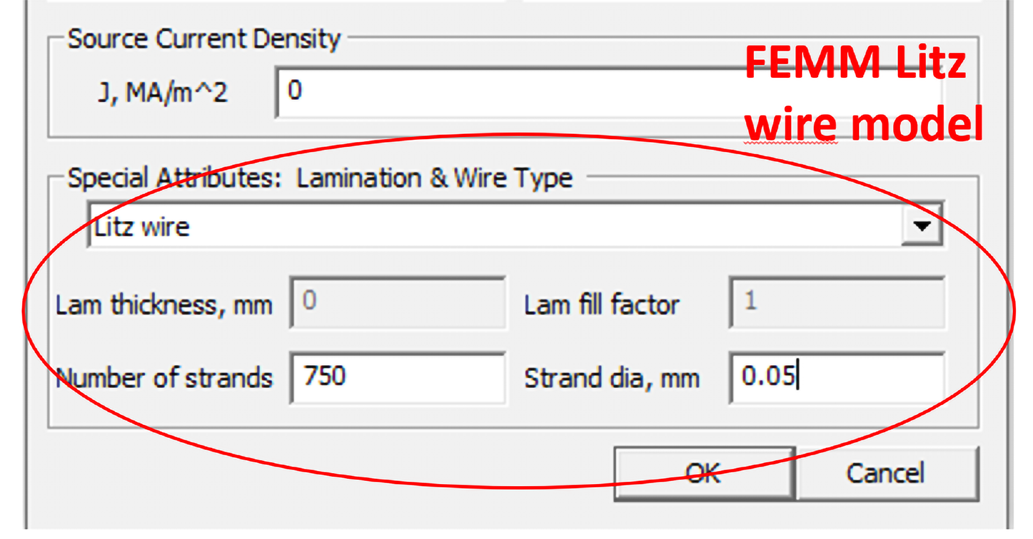

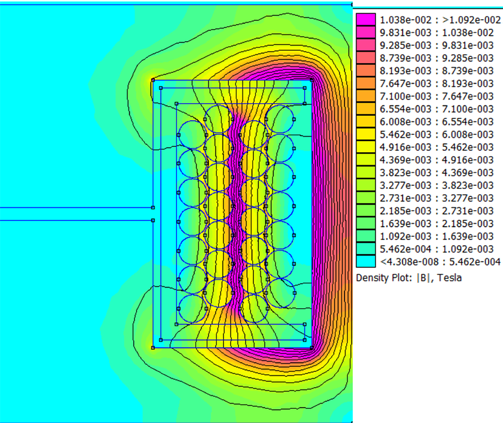

2D FEMM software [17,18] has had this module embedded for years and can be easily tried (figure 11a). Before using it massively, the question of the accuracy and robustness of copper loss calculation vs. frequency with Litz wire must be validated.

The introduction of several geometries and winding arrangements was considered when applying the Litz wire model. A short program in Octave GNU [19] enabled an automatic calculation at different frequencies to superimpose the data with real measurements of the parts by an impedance analyzer (HEWLETT-PACKARD 4194A or similar – figure 11b).

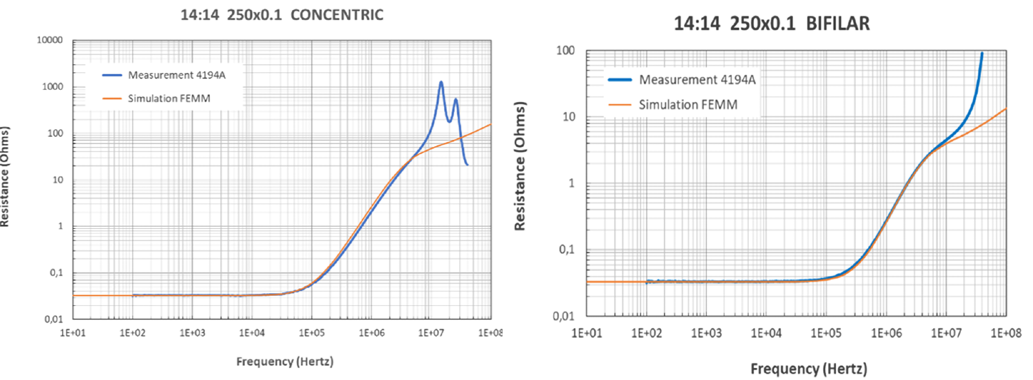

This robust and very quick computing technique has been validated on many winding configurations to check its accuracy vs. measurement. As an example, the below curves (figure 12a/b) are given for a 14:14 transformer made of 250×0.1 Litz wire windings. Of course, a bifilar winding reduces the copper losses by half the value at 300kHz by less proximity losses between primary and secondary.

Many other comparisons have been done, playing with geometries (core size), Litz wire definition and winding arrangement. As a result, this cheap, fast, and accurate simulation capability is a fully robust approach for AC losses estimation in any case that could be considered under 2D hypothesis (symmetrical or planar simplification). Therefore, quick simulation results comparison for different configurations has become a powerful method for winding losses optimization without making any sample. This is even more efficient whenever you apply our automatic FEMM model generation

from a MATHCAD page in which you have all the data around the design (core dimensions, turns and placement, wires selection, current and frequency…) [20].

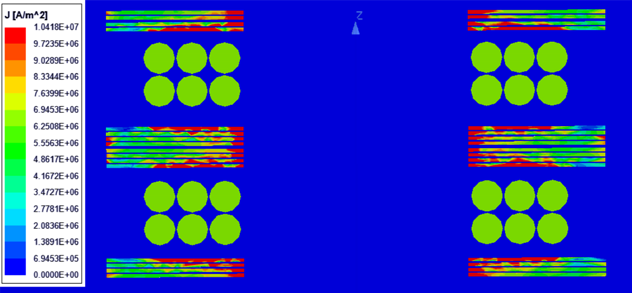

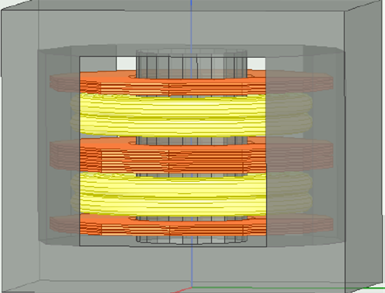

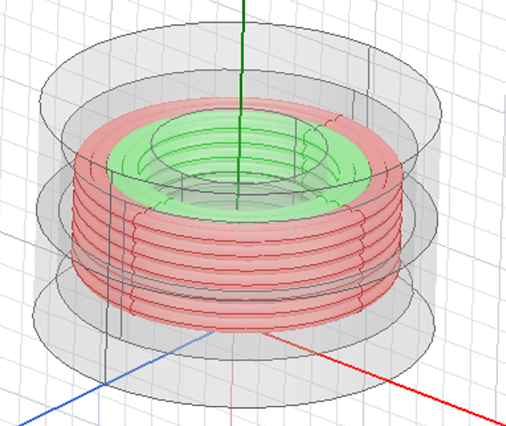

However, what about the case of any more complex geometry where 2D representation cannot be enough? Fortunately, other available magnetic FEA simulation tools can offer today a similar integrated Litz model. It is now the case of ANSYS MAXWELL from their release 2020R1 [21]. Of course, the modeling of the solution and calculation time will be less efficient but with a simplified model or from a 3D mechanical model import (STEP file or similar), good results could be obtained for complex shapes as planar transformers (figure 13). This must have been validated also and we have found a very good matching with 2D results coming from FEMM (figure 14

| DC Copper Losses | AC Copper Losses | Rac / Rdc | |

|---|---|---|---|

| FEMM 2D Axisymmetric | 4.4 W | 6.6 W | 1.5 |

| Corresponding Maxwell 3D | 4.9 W | 6.9W | 1.4 |

Figure 14 : 14:14 transformer losses comparison between FEMM 2D

and MAXWELL 3D (at 100kHz)

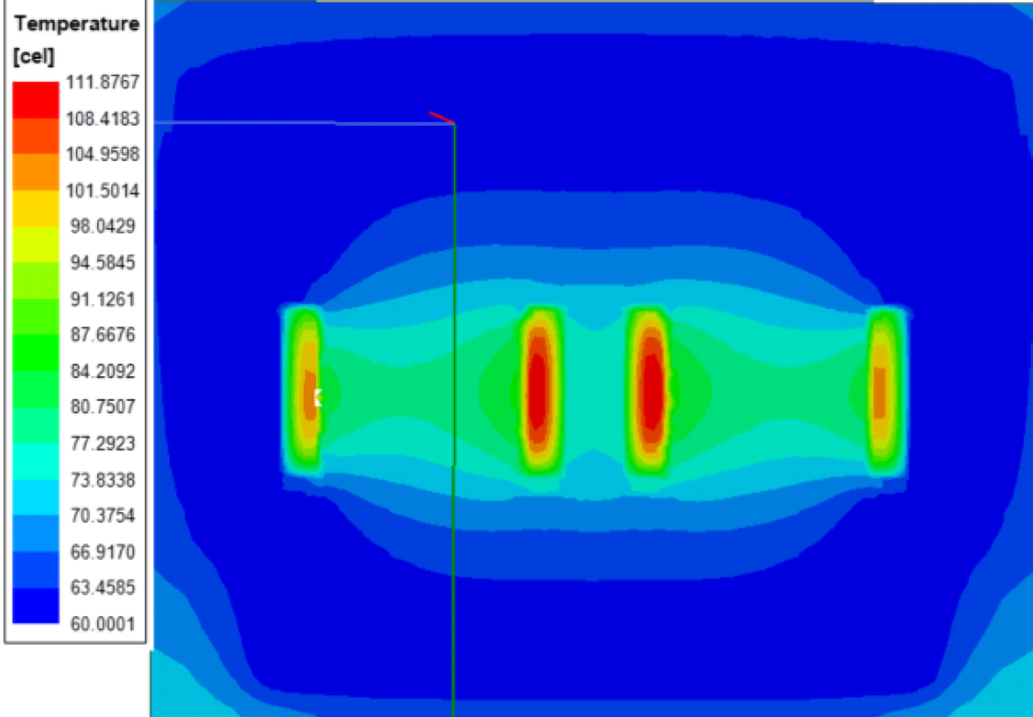

Thermal Simulation

When the losses distribution has been well identified in copper and core, the next step in the design approach of any magnetic component is to have an idea of the final temperature of the solution (that might also include some additional cooling system) for some given operating points. A thermal simulation tool like ANSYS ICEPAK can be used but here comes the question of the thermal conductivity (W/mK) to apply to every raw material (figure 15)… This question is particularly of interest for Litz wires which are not solid copper conductors. Some interesting studies by analytical approach or direct measurement are available to confirm a number [22,23]. From this experience, we can state that for an isolated Litz wire by polyimide tape, a thermal conductivity in the range of 0.5 to 1W/mK can be applied as a reference.

It exists also some analytical models that can estimate the equivalent thermal conductivity, based on the thermal resistance network applied to the single strand then generalized to the bundle and overall wire [24,25]. However, we still need to evaluate their accuracy. Another limitation is the availability of all input data. Indeed, the suppliers are not sharing all the useful parameters, as the thermal conductivity of the insulated layers, typical thickness of insulations. The lack of information can make difficult the use of the models.

When applying such simulation approach, Litz wire can even be considered in a two-way magnetic-thermal analysis to determine the steady-state operating temperature while taking temperature dependent material properties into account (ICEPAK-MAXWELL coupling).

Conclusion

In this article we reviewed the Litz wire benefits in power magnetic components subjected to switching in the medium frequency range (50-500kHz). Combined to optimized coupling in windings, it offers lower copper losses. Design guidelines for its best definition were proposed regarding frequency, current density, isolation, and temperature criteria. Well known parameters as well as additional selection modes were introduced. The good accuracy of analytical 2D/3D FEA simulation including Litz wire models was tested by comparison with the experiment. Available corresponding software are tools that engineers must use with the best practice for copper losses estimation or comparison of winding arrangement and Litz wire composition. The extension to thermal simulations is fully possible by applying a realistic equivalent thermal conductivity for Litz wire conductors.

PREMO R&D engineers follow all these steps for the best optimization of magnetic solutions especially for high power density magnetic components dedicated to embedded chargers and converters in new EV or PHEV cars.

PREMO is a Spain-based company engaged in the development, manufacture, and sale of electronic components with a special focus on the key enabling technologies of the 4th Industrial Revolution : IoT, M2M, VR, connected and electric vehicles.

Our product portfolio includes RFID antennas (worldwide leader), AR/VR motion tracking sensors, power transformers, inductors & chokes, current sensors, EMC filters, and PLC components. In addition to our broad range of standard, off-the-shelf products, PREMO also designs custom solutions to fit customer requirements, based on the latest technologies to help your systems be more efficient.

Resource Materials and Citations

[3] Litz Wire, HF-Litz, High Frequency Litz Wire, Litz Wire for High Efficiency | ELEKTRISOLA, https://www.elektrisola.com/en/Litz-Wire/Info

[9] “Simplified Design Method for Litz Wire”, C.R. Sullivan and R. Y. Zhang, IEEE Applied Power Electronics Conference, 2014

[10] “Fast Simulation of Litz Wire Using Multilevel PEEC Method”, Jiahua Lyu, Hongcai Chen, Yang Zhang, Yaping Du and Qingsha S. Cheng, IEEE Transactions on Power Electronics, Vol.35, No.12, December 2020

[11] “Litz wire losses : Effects of twisting imperfections”, Guillod, Thomas and al., IEEE 18th Workshop on Control and Modeling for Power Electronics (COMPEL), IEEE, 2017, p. 18

[12] Simplified litz wire design | Power Magnetics. https://sites.dartmouth.edu/power-magnetics/2014/06/18/simplified-litz-wire-design/

[13] “DEP Meshworks | CAE Platform for Accelerating Product Development”, Detroit Engineered Products, https://depusa.com/meshworks/

[14] “Analysis of Litz Wire Losses Using Homogenization-Based FEM”, Yoshitsugu Otomo, Hajime Igarashi, Hiroyuki Sano, Takashi Yamada, IEEE Transactions on Magnetics, vol. 57, n°8, August 2021, pp.19

[15] “A Two-Dimensional Equivalent Complex Permeability Model for Round-Wire Windings”, Xi Nan, C. R. Sullivan, IEEE PowerElectronics Specialists Conference, June 2005, pp.613–618

[16] “An Improved Continuum Skin and Proximity Effect Model for Hexagonally Packed Wires”, David C. Meeker, Journal of Computational and Applied Mathematics, 2012

[17] Finite Element Method Magnetics, https://www.femm.info/wiki/HomePage

[18] “The FEMM Package : A Simple, Fast, and Accurate OpenSource Electromagnetic Tool in Science and Engineering”, K. B. Baltzis, Journal of Engineering Science and Technology Review, 2008, pp.83-89

[19] GNU Octave, https://octave.org/index

[20] “Automatic Magnetic Simulation Generation for Inductive Components Design”, Benoit Battail and Patrick Fouassier, Bodo’s Power Systems, February 2021

[21] Using Litz Wire in Maxwell 2D and 3D Simulations, https://www.ansys.com/fr-fr/blog/using-litz-wire-in-maxwell-2dand-3d-simulations

[22] “Preliminary Design Method in Power Electronics”, Mylène Delhommais, Electrical Engineering PhD Thesis, Université Grenoble Alpes, 2019

[23] “Effective Thermal Conductivity Calculation and Measurement of Litz Wire based on the Porous Metal Materials Structure”, Xiaomei Liu, David Gerada, Zeyuan Xu, Martin Corfield, Chris Gerada, Senior Member, IEEE, Haitao Yu, IEEE Transactions on Industrial Electronics, vol. 67, n 4, April 2019

[24] “Thermal Modeling of Inductor and Transformer Windings Including Litz Wire », Phyo Aung Kyaw, Mylène Delhommais, Jizheng Qiu, Charles R. Sullivan, Jean-Luc Schanen and Cécile Rigaud, IEEE Transactions on Power Electronics, Vol. 35, n°1, January 2020

[25] “Effective Thermal Conductivity Calculation and Measurement of Litz Wire Based on the Porous Metal Materials Structure”, Xiaomei Liu, David Gerada, Zeyuan Xu, Martin Corfield, Chris Gerada, Haitao Yu, IEEE Transactions on Industrial Electronics, vol. 67, n°4, April 2020

Patrick Fouassier, Principal Engineer, PREMO FRANCE R&D Manager, Inductive Compo- nents

Patrick holds a degree in Engineering as well as a PhD in Electrical Engineering. He has more than 20 years of experience in magnetic components related to signal and power elec- tronics.

He studied at Grenoble INPG/ENSE3 engineering school and did his thesis in the G2ELab close to the Alps. After his prior position as R&D Manager at MICROSPIRE (now part of EXXELIA Group), a French company oriented towards professional markets like de- fense, avionics, and space, he joined the Spanish PREMO Group in 2008 when participating in the creation of the PREMO FRANCE office located in the Grenoble area.

Now his activity within his team is fully focused on the develop- ment and project management of innovative solutions for the automotive sector with fully optimized components for battery chargers and DC/DC converters from some kW to tens of kW used in new electrical and hybrid cars.

His R&D expertise is renowned on a worldwide scale and in a fully multidisciplinary context from customer technical support to internal training.

Benoit Battail, R&D Engineer, PREMO FRANCE, Inductive Components

Benoit has a degree in Electrical Engineer- ing specialized in power electronics from the UGA / Grenoble INP ENSE3 school.

He followed his 4th year internship at the de- partment of cybernetics engineering of NTNU Trondheim working on modelling and simu- lating the wireless charging for submarine applications.

He has been now working with PREMO for 3 years in the design of complex solutions of magnetic components for power elec- tronic converters embedded in EVs.

PREMO HUB

you might also be interested in......

At the heart of Premo’s innovation lies a compact 50KW Off Board Charger Transformer with LLC Resonant Choke set meticulously engineered to meet the demanding power requirements of modern EVs. Housed within a sleek 300 x 174 x 100 mm aluminum casing, this high-performance transformer boasts remarkable efficiency, delivering power with over …

Missed us at PCIM Europe? No worries, we’ve got you covered! Our team showcased the best of our cutting-edge E-Mobility Solutions. Off-Board Magnetics Innovative off-board magnetic for street charging stations and in-home wall-boxes. Transformers and inductors modules are ready to be mounted mechanically, connected, and cooled down, especially by air convection. …

PREMO releases its newest products, the 4CMCN065R0-16H, and 4CMCN065R0-32H, 4-Phases high-power common-mode chokes designed for EMC noise filtering in on-board chargers of up to 22Kw in electric vehicles. These automotive-grade chokes are compact in size (< 5.8 cm3) and got high efficiency (>98.5%), making them the ideal solution for electric vehicle manufacturers …