Product News - Automotive EV

Heat Dissipation Challenge in Power Integrated Magnetics – 3DPower

Heat Dissipation Challenge in Automotive High-Power Integrated Magnetics

Premo Group launched 3DPower™, the first product to integrate two magnetics components that share the same core and feature two orthogonal magnetic fields at all points within the core.

Sector: Power Electronics, Powertrain, EV/ HEV

Authors: Hector Perdomo Díaz, Juan Manuel Codes Troyano in collaboration with MSMP Power GmbH

This article focuses on discussing the advances achieved by PREMO regarding heat dissipation techniques in 3DPower™. The biggest impact of magnetic integration is volume reduction when compared to a discrete solution for the same component. A consequence of increasing the power density is a temperature rise of the part.

3DPower’s Introduction

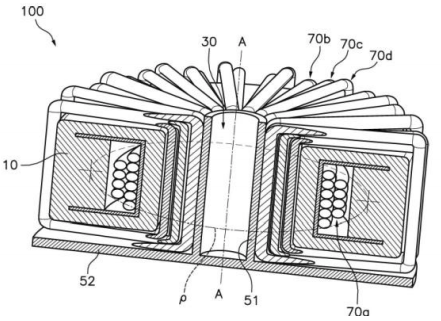

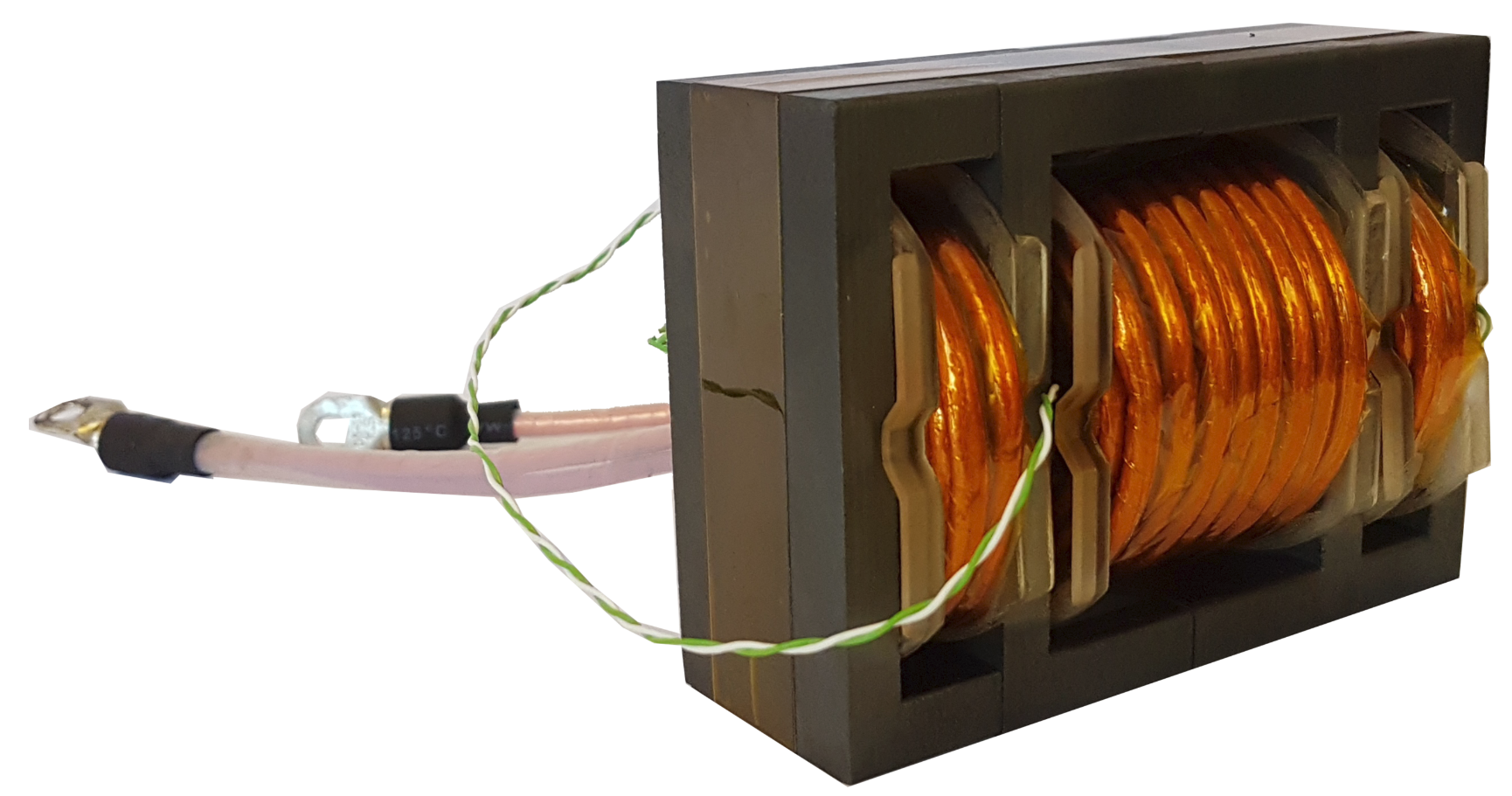

3DPower™ Pot-Core uses a custom pot-core shape where 2 inductive components are integrated. One of them is placed in the pot-core itself and the other one outside the pot-core as if it were a toroid. This product allows us to solve the engineering challenge of integrating magnetics: in this case, it consists of a choke and a transformer. Unlike other magnetics integration technologies, both components share the whole core volume in the 3DPower™. For this purpose, the magnetic field of one component is orthogonal to the other, resulting in 2 independent and fully uncoupled magnetic elements.

detailed cross-section (right)

As it can be seen in Figure 1, there is one winding inside the ferrite core (70a); while the other orthogonal winding is outside (70b/c/d). Designers of magnetics for mass production know that ferrite cores break easily, particularly when the winding is machine-made. Hence, it was necessary to cover the core with a coil. The readers can imagine how hot a core can be when it contains a winding with a few tens of amps, and it is covered by a plastic coil that has also wires around it; plus, this adds up to the core self-heating due to core losses.

Most of the times overheating failures are caused not only by the overall temperature increase but also by hot spots. Hot spots can create temperature gradients in the ferrite core that could lead into breaks or a poor performance. Therefore, the main goal in a product is to avoid hot spots by creating good thermal link between all the components and then ensure a proper cooling system to remove heat.

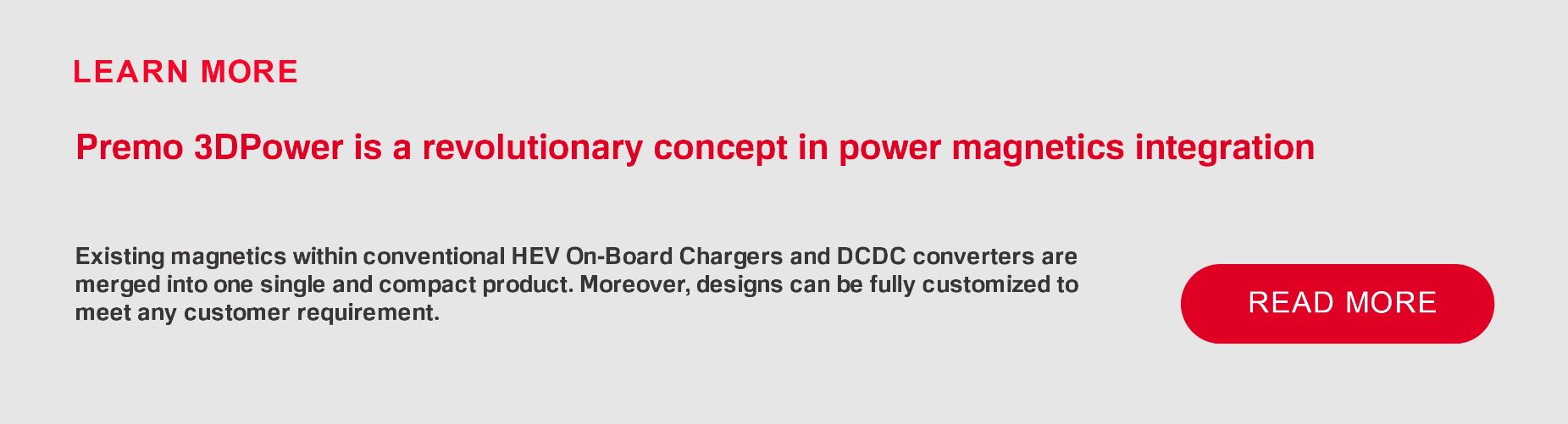

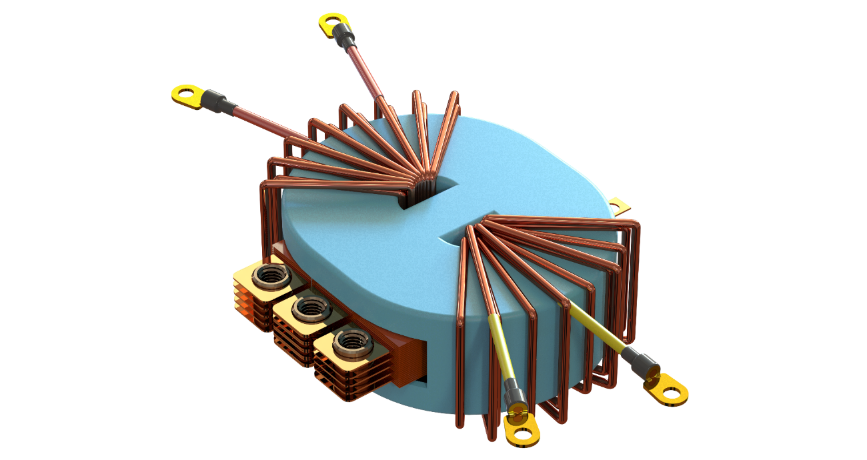

Premo can provide fully customized solutions of the 3DPower™. However, due to its geometry, the main applications are Phase-Shifted Full-Bridge and Resonant LLC DCDC converters. The output power range spans from 1 kW to 11 kW, but higher powers can be reached on demand. One of our latest developments can be seen in Figure 2, where three magnetics components are combined in one single core (1 transformer and 2 inductors). This is just one example of how easy is to integrate magnetics by using our technology.

parallel inductor for a 3.5kW LLC converter

Thermal Link

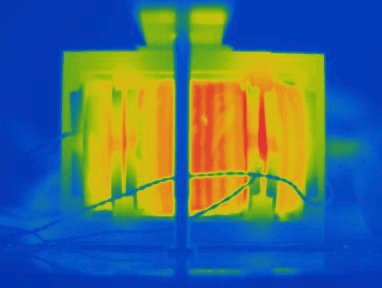

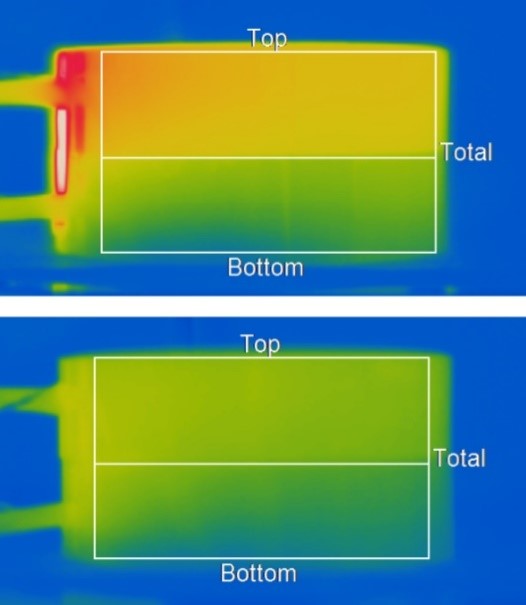

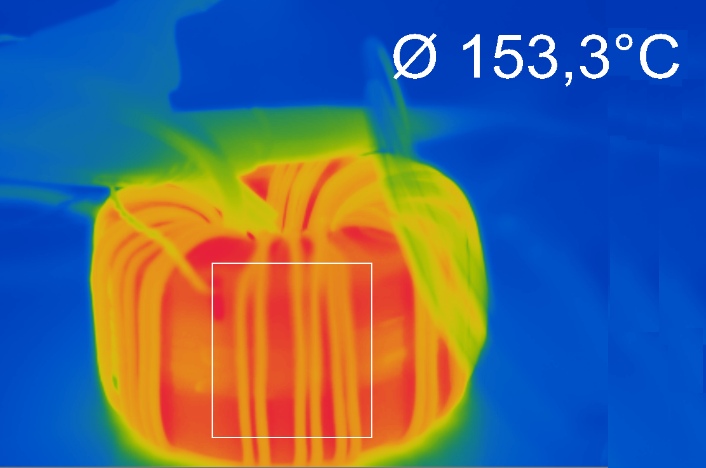

A proper design and a wide selection of materials are key for thermal performance. The picture below shows an 11kW transformer where windings were made using stereolithography 3D printing technology and cooled with water in the bottom core. The wire is much hotter than the core, particularly on the bottom.

overview of the 11kW transformer (right)

The solution consists of using thermal conductive plastics on the coils to create a thermal link between the wire and the core, for example with thermal pad or thermal liquid gap filling material. In the 3DPower™, thermal liquid gap filler was dispensed to guarantee a reliable thermal link between coils, windings and core.

Core Adhesive

Core sets are supplied in halves. The easiest and cheapest way to join two cores is to use tape, which is common for cheap and small transformers. Although the magnetic path is not affected, the thermal resistance is high between the two cores. Thus, when one of the cores is attached to a heatsink, the temperature gradient in the other one is so high that could lead into ferrite breaks.

Figure 4: Temperature gradient of core sets with different adhesives:

standard adhesive (top), high thermal conductive adhesive (bottom)

We performed tests in our R&D facilities and the results highlighted that when using a standard adhesive, the gradient of temperature between the two cores halves is twice than using a high thermal conductive adhesive. The ferrite not only can break, but also due to an inductance variation with temperature the reluctance of both cores will be different and can create unwanted performance.

Coil Plastics

As explained, the pot core will be covered with a plastic coil to protect the ferrite during the winding process and to provide electrical isolation. This coil will be exposed to the air if natural or forced convection is used and in contact to a cooling plate if water cooling is used instead.

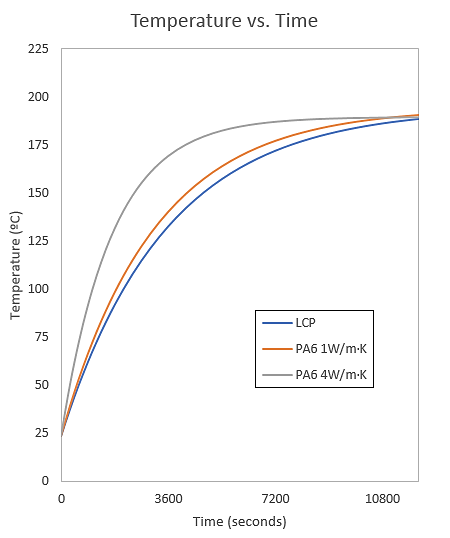

Three different plastics were tested for natural convection. The first plastic was a commonly used Liquid-Crystal Polymer (LCP) ~0.5 W/m·K thermal conductivity, the second one was a PA6-based compound (polyamide) with 1.2W/m·K thermal conductivity, while the third one was also a PA6-based plastic with 4W/m·K thermal conductivity. The three samples were prepared with thermocouples inside and tested at the same operating point. The temperatures measurements were logged and fitted according to the method of least squares (Equation 1). This equation simplifies the thermal model, which becomes a lumped capacitance model.

![]()

Results showed that the final temperature was the same for the three sample. Nevertheless, the PA6 with the higher thermal conductivity reached the steady temperature twice as fast as the other samples. This means that the “tau” coefficient of the PA6 4W/m·K sample in the lumped capacitance model equation is halved when compared to the rest.

A fast response system will show a faster ‘reaction’ to temperature variations, spreading the heat faster and therefore lowering the risks of ferrite cracks or hot spots. So, in this case the use of high thermal conductive plastics had a significant impact in the thermal behavior of the part. In the next section we will see if this also applies for the forced conduction approach

Resins

In EV/HEV vehicles, all high-power magnetics must be cooled down by means of a forced cooling technique. Since semiconductor power modules are attached to a cooling plate, this is used also to mount the magnetic components on it. Most of our clients use only thermal pads, but there is a growing trend in the industry towards the use of resins to pot the whole on-board charger or the power converter. The size of the power electronics units is reduced thanks to the better thermal dissipation and electrical isolation of the resin.

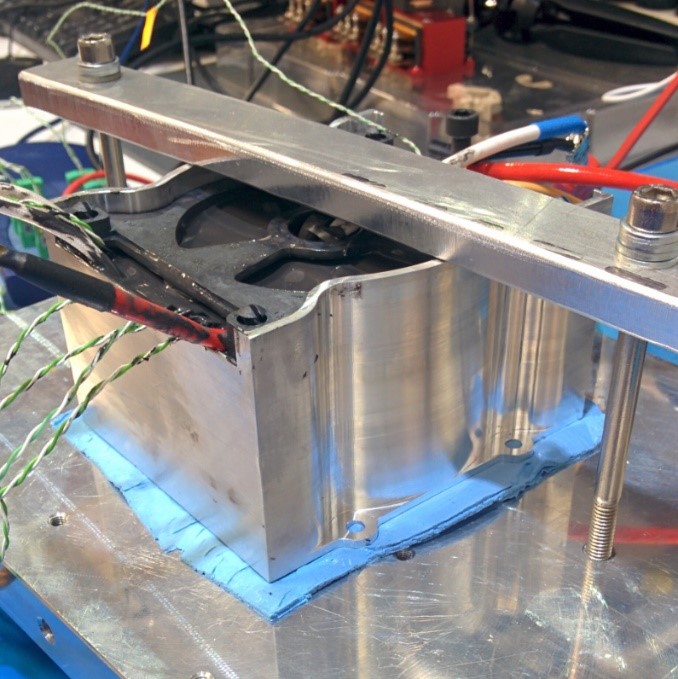

We conducted a test with PA6 4W/m·K and LCP samples, both inside an aluminum case and potted with automotive silicone resin. The cases were mounted on a cooling plate with thermal pad in between as shown in Figure 6. The purpose of this test was to check if thermal conductive plastics improve the design when potted with resins.

Results confirmed that the final temperature of the samples was similar, with a difference of only 4ºC, which is negligible if we consider thermocouples accuracy and manufacturing divergences among samples. The time response of the system was slower for the PA6 sample (25% slower).

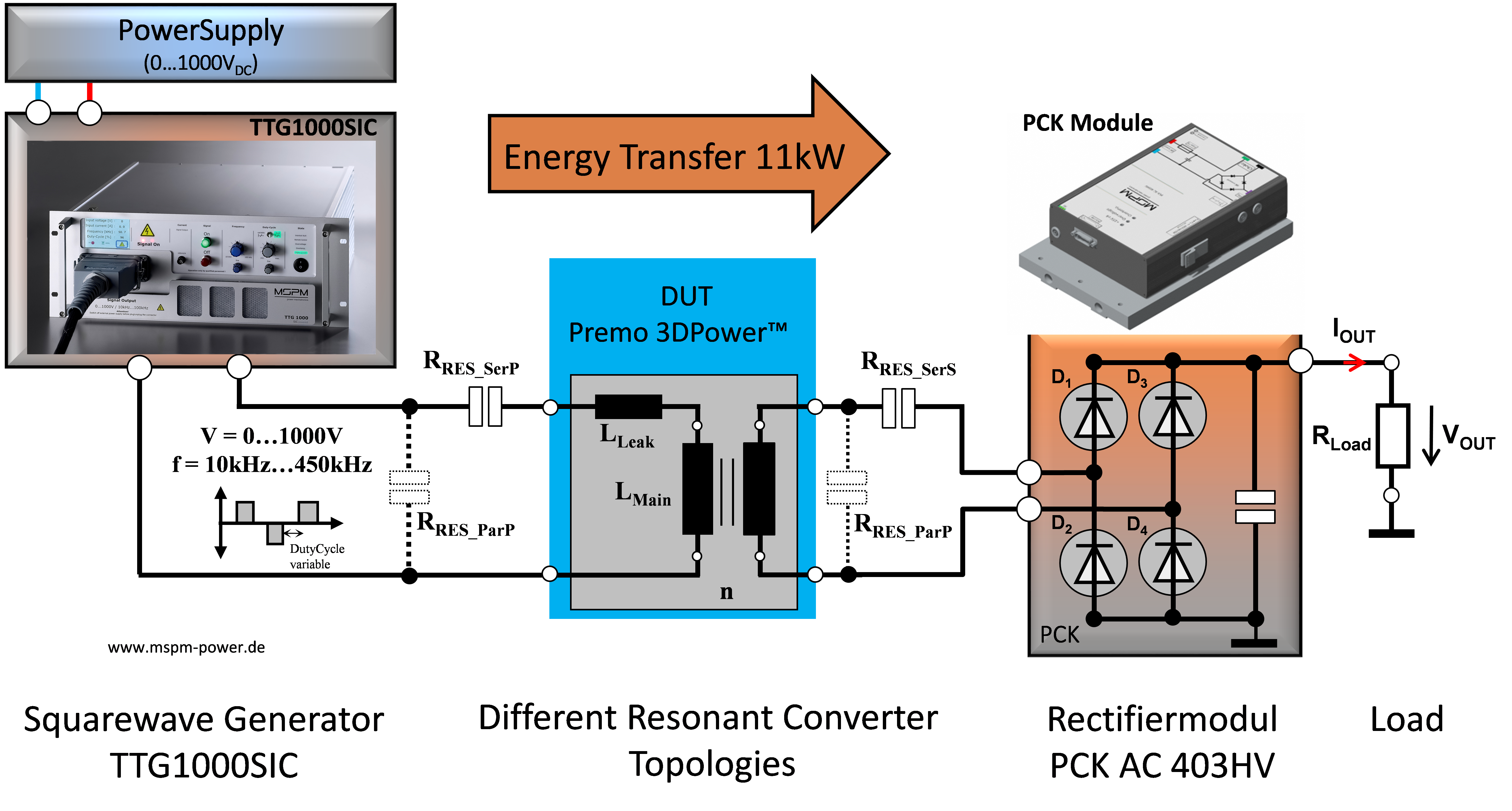

High Power Test Setup

To test the electrical and thermal performance of the 3DPower™ magnetics under all load conditions a high-power test setup from MSPM Power GmbH was used. A TTG1000SIC square wave generator is the main part of the test equipment and it generates the square wave signal of up to 1000V. The square wave frequency can be set within a range of 10 kHz to 450 kHz and it is also possible to set the duty cycle from 0 to 100%. An external full-wave rectifier module (PCK-Module) is connected to the secondary side of the transformer or the resonant circuit to convert the AC signal into a DC voltage. With this test setup it was easy to characterize the magnetic components under real-life conditions.

Conclusions

Reliability of the components is a performance point often forgotten; we only care about it when there is an issue. Most of reliability issues are related to temperature: fire, parameter variation, ferrite cracks, low performance, etc. For this reason, engineers must design and select the best materials to improve the thermal behavior.

This article has shown how relevant is selecting the optimal materials in different scenarios. First, it emphasizes the creation of good thermal links between all the components of a transformer to achieve a continuous path for the heat to the cooling source.

Then we checked how a simple thing like the adhesive of the cores could reduce the temperature gradient from 18ºC to 9ºC in our test.

Finally, we confirmed that also good thermal conductor plastic can improve the heat dissipation in some cases; however, in other cases, it may not be worth. When the part is potted with resin, a high thermal conductive plastic does not improve at all on a standard Liquid-Crystal Polymer plastic. The cost of the resin is higher, so the final decision is, as usual, a cost-performance tradeoff.

3DPower Resources

> Download the Technical article -> Bodo´s Power Article November Issue 2018

>Ebook: Temperature and heat management in power electronics (3DPower) for EV´s

> Related Webinars:

PREMO HUB

you might also be interested in......

At the heart of Premo’s innovation lies a compact 50KW Off Board Charger Transformer with LLC Resonant Choke set meticulously engineered to meet the demanding power requirements of modern EVs. Housed within a sleek 300 x 174 x 100 mm aluminum casing, this high-performance transformer boasts remarkable efficiency, delivering power with over …

Missed us at PCIM Europe? No worries, we’ve got you covered! Our team showcased the best of our cutting-edge E-Mobility Solutions. Off-Board Magnetics Innovative off-board magnetic for street charging stations and in-home wall-boxes. Transformers and inductors modules are ready to be mounted mechanically, connected, and cooled down, especially by air convection. …

PREMO releases its newest products, the 4CMCN065R0-16H, and 4CMCN065R0-32H, 4-Phases high-power common-mode chokes designed for EMC noise filtering in on-board chargers of up to 22Kw in electric vehicles. These automotive-grade chokes are compact in size (< 5.8 cm3) and got high efficiency (>98.5%), making them the ideal solution for electric vehicle manufacturers …