ZC1003-0238J

Z axis Surface Mount Z AXIS RFID...

5,00 €

168 In Stock

Menus

| Freq. (kHz) | L (mH) | Q Min | Sensitivity (mVpp/App/m) Min | Height (mm) | Length (mm) | Width (mm) | SRF (kHz) Min | Tolerance | Cres (pF) | DCR (Ω) Max |

|---|---|---|---|---|---|---|---|---|---|---|

| 125 | 2.38 | 58.5 | 20 | 3.2 | 10.0 | 10.0 | 1000 | ±5% | 680 | 27 |

| 125 | 4.91 | 72 | 25 | 3.2 | 10.0 | 10.0 | 900 | ±5% | 330 | 41 |

| 125 | 7.20 | 76.5 | 35 | 3.2 | 10.0 | 10.0 | 850 | ±5% | 220 | 55 |

| 125 | 9.00 | 81 | 40 | 3.2 | 10.0 | 10.0 | 800 | ±5% | 180 | 62 |

| 125 | 2.66 | 58.5 | 20 | 3.2 | 10.0 | 10.0 | 1000 | ±5% | 609 | 29 |

| 125 | 0.735 | 65.7 | 20 | 3.2 | 10.0 | 10.0 | 1000 | ±5% | 2205 | 5 |

|

| L (mH) | Tolerance | Q Min | Frequency (kHz) | Cres (pF) | SRF (kHz) Min | DCR (Ω) Max | Sensitivity (mVpp/App/m) Min | Length (mm) | Width (mm) | Height (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ZC1003-0073J | 0.735 | ±5% | 65.7 | 125 | 2205 | 1000 | 5 | 20 | 10.0 | 10.0 | 3.2 |

| ZC1003-0238J | 2.38 | ±5% | 58.5 | 125 | 680 | 1000 | 27 | 20 | 10.0 | 10.0 | 3.2 |

| ZC1003-0266J | 2.66 | ±5% | 58.5 | 125 | 609 | 1000 | 29 | 20 | 10.0 | 10.0 | 3.2 |

| ZC1003-0491J | 4.91 | ±5% | 72 | 125 | 330 | 900 | 41 | 25 | 10.0 | 10.0 | 3.2 |

| ZC1003-0720J | 7.20 | ±5% | 55 | 125 | 220 | 850 | 55 | 35 | 10.0 | 10.0 | 3.2 |

| ZC1003-0900J | 9.00 | ±5% | 81 | 125 | 180 | 800 | 62 | 40 | 10.0 | 10.0 | 3.2 |

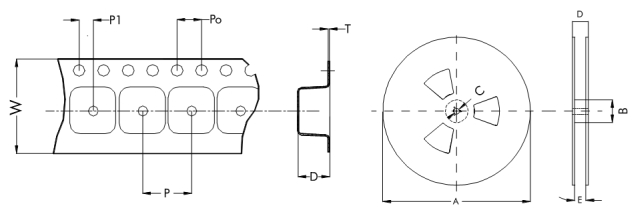

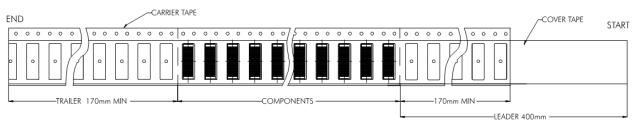

| Reel dimensions | Tape dimensions | PARTS/REEL | |||||||||

| A | B | C | D | E | W | P | P0 | P1 | D | T | |

| 330 | 50 | 13 | 30.4 | 24.4 | 24 | 16 | 4 | 2 | 4.2 | 0.3 | 1000 |

All dimensions in mm.

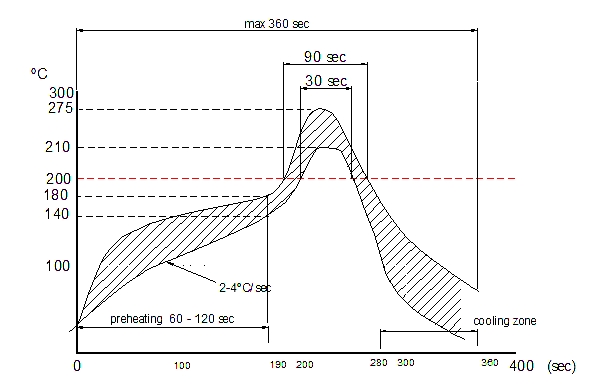

Reflow soldering, vapour-phase soldering. A maximum soldering temperature of 260ºC during 10 s should not be exceed for (see recommended soldering profile with maximum and minimum temperature-time).

The reflow condition recommended is according to the machine used by our company. Big differences will arise as a result of the type of machine, reflow conditions, method, etc used.